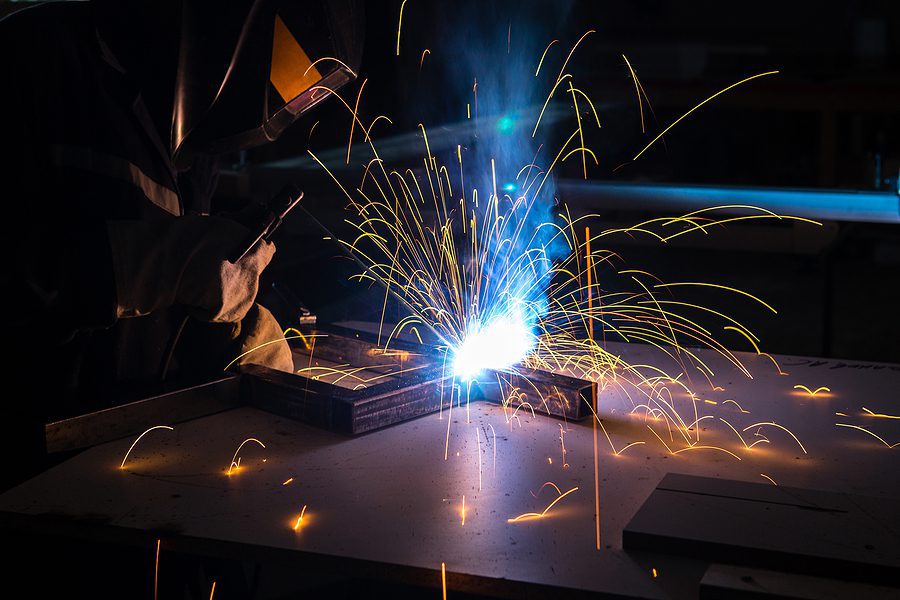

All About Welding: Trick Insights Into Techniques and Finest Practices for Success

Welding incorporates a variety of methods, each suited for specific products and applications. Understanding these techniques, such as GMAW, SMAW, and TIG, is important for attaining perfect outcomes. Moreover, the right devices and safety methods can not be neglected. As prep work and fixing play crucial duties in the welding process, mastering these aspects can substantially enhance the high quality of the last item. What are the crucial factors that assure an effective weld?

Understanding Different Welding Techniques

Welding methods include a range of methods, each matched to particular applications and materials. Among one of the most typical strategies are Gas Steel Arc Welding (GMAW), Shielded Steel Arc Welding (SMAW), and Tungsten Inert Gas Welding (TIG) GMAW, also referred to as MIG welding, is popular for its speed and versatility, making it suitable for slim materials. SMAW, or stick welding, is favored for its simpleness and efficiency in outdoor environments, particularly with thicker metals. TIG welding supplies accuracy and control, making it ideal for intricate work and non-ferrous metals (Montana Mobile Welding and Repair Belgrade Fabrication). Each strategy has its special benefits and factors to consider, allowing welders to choose the best method based on the job's needs, material kind, and wanted end results. Recognizing these methods is vital for successful welding

Vital Welding Devices and Tools

While numerous welding techniques need certain abilities, the appropriate equipment and devices are just as important for achieving top quality outcomes. Crucial welding devices includes welding machines, which vary relying on the method-- such as MIG, TIG, or stick welding. Safety gear, including aprons, headgears, and handwear covers, guarantees safety and security and convenience throughout the process. In addition, clamps and components aid safeguard materials in position, guaranteeing precision in welds. Consumables like welding rods, wire, and protecting gas are additionally crucial parts that influence the quality of the weld. In addition, devices such as cutters and grinders facilitate surface prep work and post-weld finishing, adding to a specialist end result. Purchasing top notch devices inevitably boosts the performance and effectiveness of welding tasks.

Safety Practices in Welding

Appropriate security methods are important in the welding sector to secure workers from possible threats. Welders must wear suitable personal protective tools (PPE), including safety helmets with correct shading, gloves, and flame-resistant garments. Adequate air flow is important to reduce exposure to dangerous fumes and gases produced during the welding procedure. In addition, employees should be trained in the proper handling of welding devices to prevent mishaps. Fire precaution, such as keeping flammable products far from the welding location and having fire extinguishers easily offered, are essential. Normal evaluations of equipment and offices can assist recognize possible risks before they bring about mishaps. By adhering to these safety techniques, welders can develop a much safer working atmosphere and minimize risks related to their trade.

Readying Products for Welding

Preparing materials for welding is an important action that greatly affects the quality and honesty of the final item (Belgrade Fabrication). Appropriate prep work includes cleaning up the surfaces to eliminate impurities such as dust, oil, and rust, which can jeopardize the weld. Strategies such as grinding, sanding, or using solvents are commonly used to achieve a tidy surface. Additionally, making certain that the materials fit with each other comfortably is important; gaps can cause weak welds. It's likewise crucial to consider the placement and positioning of the elements, as this will certainly affect the simplicity of welding and the last result. Ultimately, picking the ideal filler product and guaranteeing compatibility with the base steels is crucial for achieving solid, resilient welds

Tips for Achieving High-Quality Welds

Attaining high-grade welds requires focus to information and adherence to ideal techniques throughout the welding procedure. Appropriate joint prep work is crucial, ensuring surface areas are cost-free and clean from pollutants. Selecting the appropriate filler material and welding strategy based upon the base metals is crucial for ideal bonding. Keeping consistent travel rate and angle while welding can protect against problems and advertise harmony. Additionally, managing warm input is essential; extreme heat can bring about bending and compromised joints. Regularly checking the welds throughout the process get more info allows for prompt adjustments if necessary. Lastly, employing proper post-weld treatments, such as cleansing and stress relief, can improve the resilience and stability of the weld, inevitably making sure a successful end result.

Fixing Common Welding Issues

Welding commonly presents challenges that can impact the quality and honesty of the end product. Common issues such as porosity, inconsistent weld grains, and overheating can occur, each calling for particular fixing strategies. Understanding these troubles is important for welders to boost their skills and accomplish perfect results.

Porosity Problems Described

Porosity can usually be ignored, it stays a vital concern in welding that can jeopardize the integrity of a completed item. Porosity refers to the presence of tiny gas pockets within the weld grain, which can compromise the joint and lead to premature failing. This problem commonly develops from pollutants, wetness, or improper securing gas insurance coverage throughout the welding process. To reduce porosity, welders should verify that the base products are completely dry and clean, utilize appropriate protecting gases, and keep constant welding parameters. On a regular basis checking the equipment and environment can also help recognize potential concerns prior to they manifest in the weld. Addressing porosity properly is important for accomplishing strong, resilient welds that satisfy quality requirements.

Irregular Weld Beans

Irregular weld grains can substantially influence the quality and strength of an ended up item. Various variables add to this issue, including incorrect travel speed, wrong amperage setups, and irregular electrode angles. When the welder moves as well quickly, a grain may appear narrow and do not have infiltration, while moving as well slowly can create too much buildup. In addition, utilizing the wrong amperage can result in either undercutting or too much spatter, both of which compromise weld stability. The welder's method, such as inconsistent lantern movement, can additionally cause unequal grain appearance. To reduce these issues, welders must concentrate on maintaining steady, controlled motions and making certain correct tools settings to accomplish harmony in their welds. Consistency is key to accomplishing reputable and strong welds.

Overheating and Warping Issues

Excessive heat throughout the welding process can cause significant overheating and deforming concerns, influencing the structural stability of the workpiece. These problems frequently show up as distortion, which can jeopardize positioning and fit-up, making further assembly challenging. Aspects contributing to overheating consist of the selection of welding criteria, such as voltage and travel speed, along with the kind of material being bonded. To minimize these problems, welders ought to preserve consistent travel speed and appropriate warmth input while monitoring the work surface temperature level. Additionally, preheating or post-weld heat therapy can help minimize anxieties triggered by rapid cooling - Welding. Normal examination and adherence to best methods are necessary in avoiding overheating and making sure the longevity and reliability of bonded frameworks

Regularly Asked Questions

What Are the Career Opportunities in the Welding Industry?

The welding sector supplies diverse profession chances, including positions as welders, engineers, examiners, and teachers. Specialists can function in production, construction, aerospace, and automobile sectors, profiting from solid need and affordable incomes in various duties.

Exactly How Can I Improve My Welding Rate Without Compromising Quality?

To enhance welding speed without compromising high quality, one should exercise effective strategies, preserve tools, maximize settings, and improve hand-eye sychronisation. Regular training and looking for feedback can also significantly add to attaining much faster, top quality welds.

What Certifications Are Available for Welders?

Many certifications exist for welders, including those from the American Welding Society (AWS), the National Facility for Construction Education And Learning and Study (NCCER), and various industry-specific organizations. These qualifications improve employability and demonstrate ability proficiency.

How Does Welding Influence the Characteristics of Metals?

Welding affects the residential properties of steels by changing their microstructure, which can cause adjustments in hardness, toughness, and ductility. Warm input and air conditioning prices throughout the procedure significantly influence these product attributes.

Can I Weld Dissimilar Metals Together?